Premium Chocolate Production Perfected: AI's Role in Quality Excellence

Lindt & Sprüngli, a global leader in the premium chocolate sector, has partnered with EthonAI, a spin-off from ETH Zurich. EthonAI develops software tools that support manufacturers achieving operational excellence using causal AI. Lindt & Sprüngli is leveraging EthonAI's tools to perfect the production of their chocolate and achieve best-in-class performance.

The "Lindor" truffles from Lindt & Sprüngli are world-renowned among chocolate lovers. These truffles have been sold since 1969, when they were introduced as a seasonal treat and they were used as actual decorations to hang on Christmas trees. Half a century later, billions of Lindor truffles are made every year. To produce at such a large scale while maintaining quality excellence, Lindt & Sprüngli runs several high-end factories in Europe and the US.

Producing Lindor truffles is a complex process that spans from ensuring the quality of the cocoa beans, through manufacturing, to logistics. The production of Lindor truffles involves multiple production steps such as molding, filling, and packaging. While the overall production setups are consistent across factories, local differences in factory infrastructure, product variants, and machine age create challenges in finding the optimal parameter settings for obtaining perfect Lindor truffles. Additionally, seasonal variations in conditions like air humidity and ambient temperature play critical roles in the production process. Therefore, understanding the interplay between process parameters and environmental factors is essential to ensure consistently high quality – and that’s where EthonAI comes in.

A complex, multi-step process

Lindt & Sprüngli has a strong commitment to excellence that goes beyond the quality and taste of their products. “Our employees have vast knowledge that we use to improve our production.“says Jessica Valli, Program Manager for Digital Transformation in Operations, “to support them, we must provide them relevant facts and information.” For this, Lindt & Sprüngli records a lot of process and quality data. “We were looking for new ways to leverage it,” explains Valli. “For example, a recurring problem was to identify and eliminate the root causes behind quality deviations and inefficiencies in production. We were happy to learn that EthonAI could help us solve this important problem.”

ETH AI Center startup affiliate EthonAI spun out of the Chair of Production and Operations Management at ETH Zurich to develop software tools that detect, monitor, and prevent quality losses in manufacturing. The tools use causal AI technology to help discover and understand the physical relationships between process parameters and quality outcomes. In this way, manufacturers can fine-tune their processes, and thereby prevent costly quality losses.

Standardizing quality management across countries

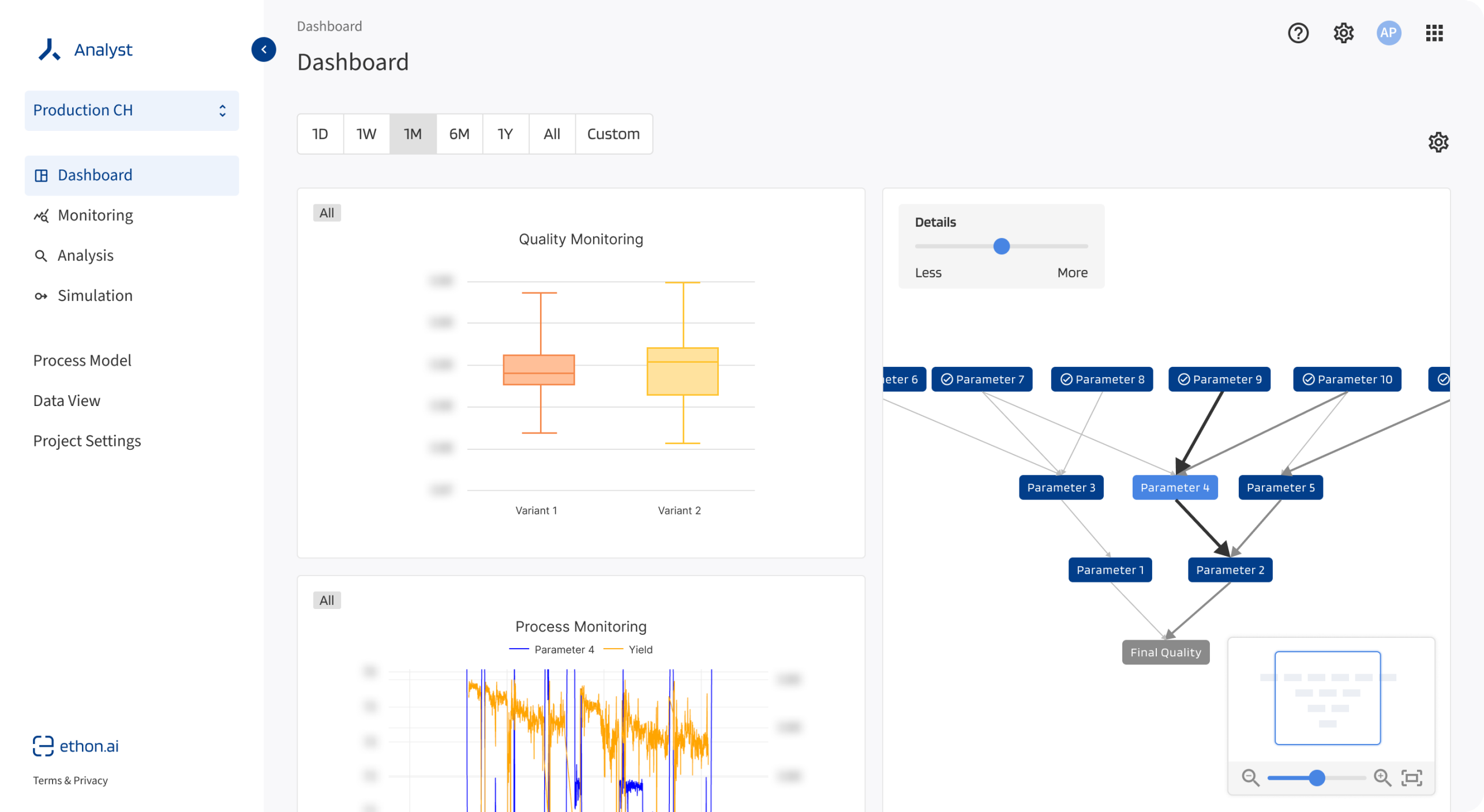

At Lindt & Sprüngli, the EthonAI tools connect the process data from the Lindor production lines with the data from factory quality control systems. This gives the line managers and production teams a holistic overview of their production lines with their dozens of parameters and quality measurements. All these data matter for optimizing local production. In addition, it provides Lindt & Sprüngli a birds-eye view on data and performance from several factories, enabling group-level learning and standardization in quality management across countries in a simple format. The EthonAI software is live in Lindt & Sprüngli factories in three countries across two continents.

By understanding the complex interactions between the process parameters and negative quality outcomes the process experts at Lindt & Sprüngli are able to take action more quickly and decisively. Ultimately, the focus is on the prevention of production issues, and discovering root causes from the real-time data fed into the EthonAI analysis tool is essential for going beyond reactive measures. For example, production experts use EthonAI’s software to fine-tune machine temperatures or mold configurations to avoid quality losses proactively. This is possible because EthonAI’s tools rely on causal AI to go beyond mere correlations, and suggest improvement actions ranked by their overall impact on the final quality. In essence, EthonAI’s causal AI can simulate the effect of potential improvement actions, so it can be tried out before adjusting the physical production.

“It’s great to see an industry leader like Lindt & Sprüngli taking such strides to implement the latest developments in AI,” says Dr. Julian Senoner, Co-founder of EthonAI. “Gartner, one of the most renowned market research firms in the technology sector, had predicted the rise of causal AI in 2-5 years. Yet, Lindt & Sprüngli is leveraging this technology already now.”

Collaboration is key

The collaboration between Lindt & Sprüngli and EthonAI showcases the great potential of combining Swiss industry leadership with startup innovation from ETH Zurich. This relationship not only benefits both parties but also sets a precedent for other industry leaders. “By embracing new technologies and being willing to adapt, the Swiss manufacturing sector remains relevant and competitive in today's fast-paced digital world.” says ETH Professor Torbjørn Netland.

The ETH AI Center has supported EthonAI since its graduation from the Talent Kick program in 2021. “I am excited to see our affiliated start-up, EthonAI, making a difference in the industry. The partnership between Lindt & Sprüngli and EthonAI reaffirms our commitment to driving innovations that benefit the broader Swiss industrial ecosystem.” says Alexander Ilic, Executive Director of the ETH AI Center. By bridging the gap between cutting-edge research and real-world applications, the AI Center ensures that the Swiss industry continues to lead on the global stage, marrying tradition with innovation.

About EthonAI

external page EthonAI is a spin-off from ETH Zurich and the ETH AI Center, providing an AI-based quality management platform for manufacturing companies. Founded by former ETH researchers Dr. Julian Senoner and Dr. Bernhard Kratzwald, together with Prof. Dr. Torbjørn Netland, EthonAI has raised more than USD 8 million in funding from internationally renowned investors. EthonAI counts several Fortune 500 companies among its customers, and is integrated into production lines across Europe and the US.

About Lindt & Sprüngli

external page Lindt & Sprüngli has been enchanting the world with chocolate for over 175 years. The traditional Swiss company with its roots in Zurich is a global leader in the premium chocolate sector. Today, Lindt & Sprüngli produces quality chocolates at its 12 factories in Europe and the USA. Its products are sold by 32 subsidiaries and regional offices, in around 500 of its own shops, as well as via a network of more than 100 independent distributors around the globe. With more than 14,000 employees, the Lindt & Sprüngli Group reported sales of CHF 4.97 billion in 2022.